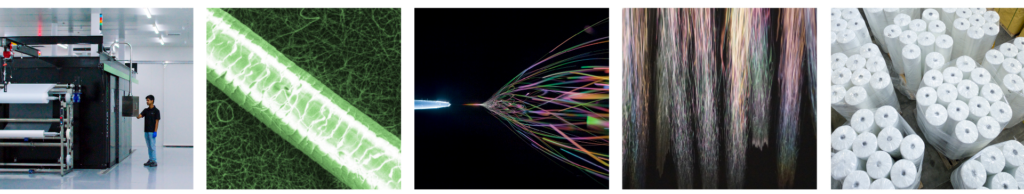

From initial concept to market, our world-leading electrospinning teams in New Zealand and the United Kingdom work with you to support and develop bespoke nanofibre solutions for your specific application requirements.

Utilising a refined development platform, NanoLayr will guide and develop your material needs through to large scale supply, an all-in-one pain-free solution to nanofibre product development.

Through partnership, collaborative or consultancy models, our R&D development teams develop novel electrospinning materials for new market applications. Our R&D services cover literature review, concept development, feasibility studies, prototyping and production scale-up, a full TRL1-9 platform.

In a fast-paced world market, we understand speed is critical for your products. That’s why at NanoLayr a typical project from ‘fresh idea’ to ‘manufacturing ready’ takes as little as 6-months, whereas elsewhere it would normally take years.

Cosmetics, Dermal Treatments, Sheet Masks, Defence, Medical Devices, Supercapacitor Separators, Battery Separators, Medical Monitoring Garments, High Volume Filtration, Waterproof Breathable Membranes, CO2 Capture, COVID-19 Swabs, Composite Interlaminar Reinforcement, Acoustic Attenuation, Liquid Filtration, Cellular Scaffolds, Mussel Farming, Battery Electrodes, HEPA Filtration, Mosquito/Insect Repellent Fabric, Sensors and Electronics, Tissue Engineering and Regenerative Medicine, Drug Delivery, Artificial Skin Grafts, Lab grown food.

Polylactic Acid (PLA), Cellulose Acetate, Polycaprolactone (PCL), Nylon (various), Polyesters (various), Polyethylene terephthalate (PET), Polyvinylidene fluoride (PVDF), Polyethylene oxide/glycol (PEO/PEG), Polyvinyl Alcohol (PVOH), Polyhydroxybutyrate (PHB), Polyacrylonitrile (PAN), Polyurethane (PU), Polyvinyl butyral (PVB), Polyamic acid (PAA), Poly(methyl methacrylate) (PMMA), Polycarbonate Urethane (PCU), Collagen, Lignin, Thermoplastic elastomers (TPE), Graphene more as an additive, Polybenzimidazole (PBI), Poly (lactic-co-glycolic acid), Ethylene vinyl alcohol (EVOH), Acrylonitrile butadiene styrene (ABS), Polyamide-imide (PAI), Polycarbonate (PC), Polyether sulfone (PES), Polyvinyl butyral (PVB), Poly (vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP), Styrene-ethylene-butylene-styrene (SEBS), Poly (3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS), Gelatin, Keratin, Cellulose Acetate, Thermoplastic polyurethane (TPU) , Polystyrene (PS), Polysulfone (PSU), Dextran, Pullulan, Seaweeds, Alginates.

Contact us to discuss your electrospinning and nanofibre requirements.